Shaping ERP3 standard to manage corporate information systems in the time of Industry 4.0

- Подробности

- Опубликовано: 14.07.2018 21:11

- Автор: Dmitry Yu. Stepanov

- Просмотров: 11796

Abstract: the paper describes the fourth industrial revolution and its impact on corporate information systems. The technical details of the fourth industrial revolution are considered, as well as ERP2 standard of corporate information systems. A new ERP3 management standard is formulated, focused on Industry 4.0 and including components of machine learning, internet of things, blockchain, robots and virtual reality.

Download: PDF.

Keywords: industry 4.0, ERP2-system, ERP3-system, digital transformation, fourth industrial revolution, industrial internet of things, IIoT, robotic process automation, RPA, virtual reality, VR, SCADA-system, blockchain, ERP3 standard, big data.

I. Introduction

Artificial intelligence and machine learning, household and industrial internet of things, data science and big data, blockchain and robots, digital and virtual reality, all this is united by a single term Industry 4.0, which often means the fourth industrial revolution, announced at the end of 2015 at the World Economic Forum in Davos. The third industrial revolution that preceded it allowed us to move to the mass use of digital technologies due to evolution of computers and the internet. Corporate information systems that support the most representative ERP2 management standard are used everywhere to automate business activities of an organization [1]. In fact, ERP2-systems are essential part of the third industrial revolution. How will the fourth industrial revolution change the composition of such class of systems? In this paper, we will try to give an answer to the question asked.

II. State of art

Over the past few years, popularity of questions related to the fourth industrial revolution and digital transformation that is its logical conclusion has increased. A large number of scientific papers have been written demonstrating transition of enterprises to the digital format. On the pages of articles and books, some authors discuss the prerequisites and composition of Industry 4.0 [2], other researchers explore the features of digitalization and subsequent digital transformation [3-4]. However, these works rarely mention the relationship with corporate information systems. Some scientists describe the standards of corporate systems and history of their evolution [5-7]. Such books are declarative in nature and do not improve or develop existing classes of information systems. An attempt to link industrial revolutions and ERP2-systems is made in the conference thesis [8]. The statement «Digital transformation, focused on establishing a continuous relationship between "processes-applications-data", will require creation of a completely new classes of information systems extending already existing ERP2-systems» does not give a clear understanding of what changes are exactly needed. Thus, questions concerning the use of corporate information systems in context of the fourth industrial revolution and, in fact, evolution of these systems remain untouched.

III. Problem statement

The purpose of this paper is to propose a new standard for corporate information systems that expands well-known ERP2 due to fourth industrial revolution. This will allow you to respond in a timely manner to changes in technologies and reflect them in a similar class of software systems. To achieve the goal following tasks to be resolved: consideration of technical details of the fourth industrial revolution, familiarization with the ERP2 standard, as well as proposal of a new standard to manage corporate information systems.

IV. Overview

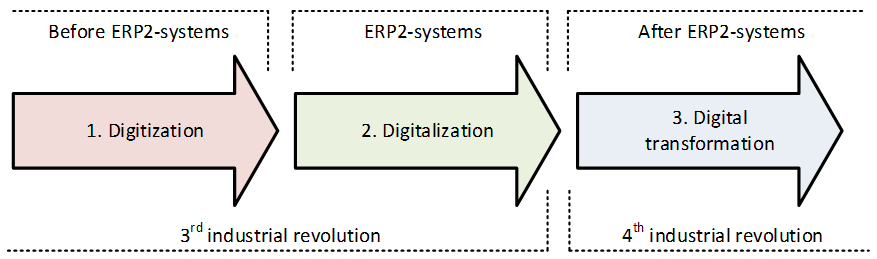

The third industrial revolution or, as it is often called, the digital revolution, is still ongoing. Its idea is the widespread replacement of analog technologies by transferring all transactions of enterprise to the digital format. The main stages of conversion to digital format include (Fig. 1): digitization, digitalization and digital transformation.

Fig. 1. Mapping digitalization steps, industrial revolutions and corporate information systems

Digitization can be described as the transformation of processes performed manually to business operations implemented using database management systems. Digitalization allows optimizing business operations using digitized data and new software solutions. However, new program solutions only follow the previously defined business model of organization and do not change it. The stage of digital transformation is characterized by a comprehensive transformation of company's work and transition to a completely new business model, products and services, business and production processes, ways of involving suppliers and customers, which are based on fundamentally new approaches to data management and digital technologies. The prerequisites for transformation are the digitization and digitalization of organization's data and processes.

As you can see from the figure above, the third industrial revolution affects the stages of digitization and digitalization, where ERP2-systems are used exclusively for digitalization tasks. Industry 4.0 requires global changes in business model and creation of radically new types of corporate systems, which corresponds to the stage of digital transformation. Thus, the last two industrial revolutions are continuously connected with corporate information systems. Let's look at additional functionality is needed in the context of the fourth industrial revolution.

The main reason for Industry 4.0 is high technological progress achieved over the past 10-15 years. Increasingly, software applications have been developed on the basis of cloud technologies and digital platforms, 3D-printers are used to create both the smallest human organs and huge machines, drones allow you to track the progress of construction buildings and artificial intelligence helps to find violators in a crowd of people. The fourth industrial revolution is distinguished by following five technical components: industrial internet of things (IIoT, integration of devices into a single computer network in a scale of enterprise), big data (high volume data arrays, processed using special software tools for the purposes of decision-making), robots (RPA, robotic process automation), blockchain (secured channel for transmitting data) and virtual reality (VR, surrounding world, artificially created with the help of technical and software tools). The key feature of Industry 4.0 is that all the listed components must continuously interact with each other.

Corporate information system is a set of information systems united by a common document flow, where each system participates in decision-making and all systems together ensure the effective functioning of enterprise. Information system optimizes a certain area of enterprise, for example, warehouse logistics, master and transactional data, accounting and tax. The term standard is used to define the company's automation area, for instance, SCM (Supply Chain Management), PLM (Product Life-Cycle Management), CRM (Customer Relationship Management), ERP (Enterprise Resource Planning) and others. Currently ERP2 standard covers the largest number of business processes of organization, although in practice they are quite rare. Then ERP2-system is one of the varieties of corporate systems that allows you to automate the business operations of an enterprise, including logistics (LO), finance (FI), human resources (HCM), supply chains (SCM), supplier and customer relationships (SRM and CRM, respectively), electronic commerce (e-Com) and product life-cycle (PLM) [6]. One way to classify corporate information systems is using enterprise management levels. Thus, in [9] it is proposed to distinguish between analytical, transactional and technical levels, which include such standards as: BI, ERP/ERP2, MES and SCADA. Following the figure below, SCADA-systems process business transactions from operational point of view, MES-systems are necessary for tactical work and remaining systems define enterprise strategy.

V. Implementation

In essence, we need to solve two seemingly unrelated tasks, one of which is the need to manage all unique components of the fourth industrial revolution. The second task requires updating the obsolete ERP2 standard, proposed back in 1996, after which dozens of new low scale standards were introduced.

To do that we need to group the tasks of implementing all the components of Industry 4.0 by areas: applications, data and technical infrastructure, implying presence of business processes describing them. Then implementation of functionality for blockchain, robots and virtual reality will require mainly application refinement, internet of things will demand software and technical changes, big data will lead to improvement of database management and analysis systems. There are similar areas available in ERP2-systems deployment projects. Thus, we can map components of ERP2-systems and Industry 4.0.

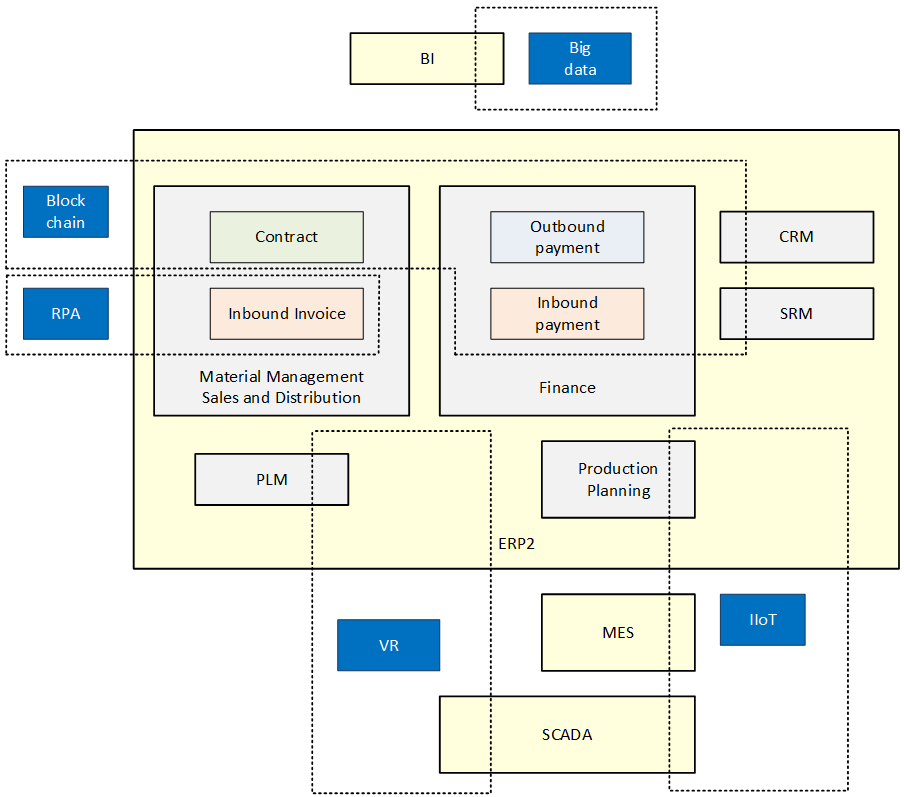

Corporate information systems define various levels of company management and potentially can be aligned with the following components of Industry 4.0 (Fig. 2):

- RPA is already used in ERP2-systems for the robotic registration of incoming invoices from suppliers, which refers to the procurement functionality.

- Blockchain is applicable to manage contracts, post inbound and outbound payments from customers and suppliers, which is relevant to business processes of procurement, sales and finance in ERP2 and partly in SRM, CRM-systems.

- Big data will obviously expand functionality of BI-systems, allowing you to get more accurate forecast about customers and their needs from various information sources.

- The industrial internet of things combines three completely different types of systems into a single environment: ERP2 in terms of functionality of strategic production, MES and SCADA, this will ensure a more transparent, well-coordinated and integrated production process.

- Virtual reality functions will be useful for modeling samples of finished goods and replacement of spare parts when repairing equipment in ERP2 and MES-systems.

Industry 4.0 leads to a complete revision of the enterprise's management levels. The functionality of ERP2, BI, MES and SCADA-systems can be improved either by altering existing applications which is unlikely or by implementing completely new independent classes of systems, such as RPA, blockchain, big data, IIoT and VR integrated with ERP2-system through middleware.

Fig. 2. Enrichment of ERP2-system by the components of Industry 4.0

Taking into account evolution of corporate information systems, it is highly likely that the components of Industry 4.0 will be placed in separate independent subsystems. The use of independent subsystems is also confirmed by the following:

- ERP2-systems are considered as core systems to ensure compliance with the accounting and tax requirements of the country. That is why they are often called registration systems [10]. All other subsystems are subordinate to the master-system.

- Digital transformation requires creation of a completely new business model to interact with third parties. However, accounting and tax requirements are still valid and to be covered by core functionality of ERP2-system. Therefore, conducting transformation in separate subsystems without explicitly changing master system is quite reasonable.

- Changing technologies require implementation of new system functions. Constant redevelopment of ERP2-system functionality seems excessive, time-consuming and risky because typically it has been working successfully for several decades. Then implementation of additional functions in new subsystems and their subsequent integration with master-system will provide a high flexibility.

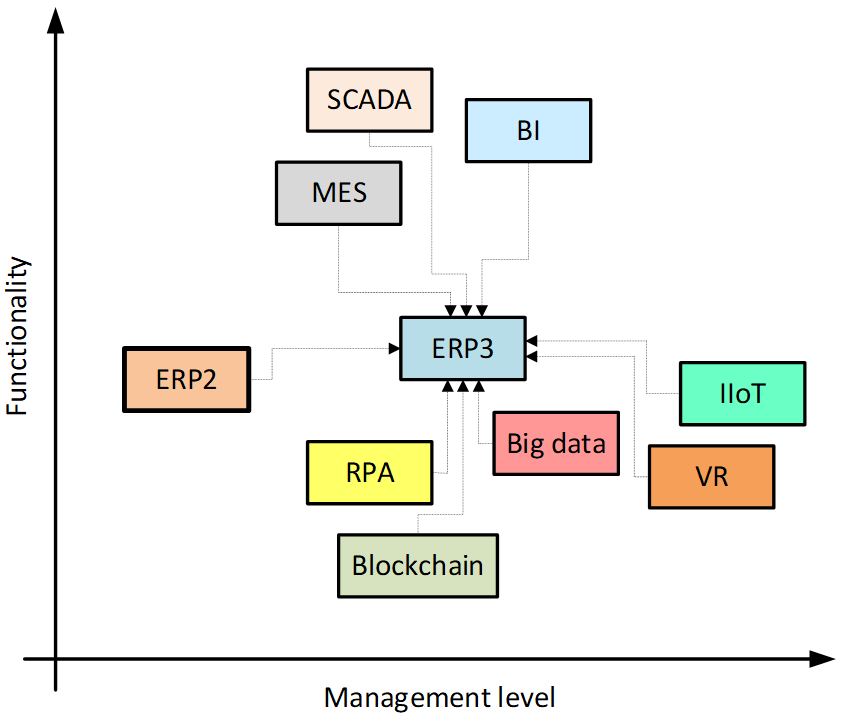

Then evolution of ERP2 standard will be its addition by the considered components of Industry 4.0. The figure below (Fig. 3) shows the scheme of new standard, supplemented by RPA, blockchain, big data, IIoT and VR subsystems and also includes such classes of systems as ERP2, BI, MES and SCADA. Let's call this standard ERP3.

Definition 1. ERP3 standard is a strategy for integrating logistics, finance, human resources as well as managing relationships with suppliers and customers, supply chains, product life-cycle and electronic commerce, focused on optimizing enterprise resources by using specialized software and modern digital technologies of robots, blockchain, big data, industrial internet of things and virtual reality.

Definition 2. ERP3-system is a corporate information system based on ERP3 standard, including ERP2, BI, MES, SCADA solutions as well as digital technologies related to Industry 4.0.

Fig. 3. Components of ERP3 standard

Definitions 1-2 strongly depend on the content of Industry 4.0. If composition of Industry 4.0 changes, for example, a new digital solution is added, then it will expand ERP3-system functionality by additional independent subsystem like IIoT, VR, RPA, etc. The feature of ERP3 standard is that it erases borders between the management levels of enterprise. If earlier ERP2-systems mainly operated at the transactional level, now both analytical and technical components are taken into account. Thus, a continuous logical connection is established between ERP2, BI, MES and SCADA-systems. From a technical point of view, interaction of all four types of systems will be carried out by integration via middleware, as it is already implemented now.

Table 1. Integration of systems under ERP3 standard

| System | ERP2 | BI | MES | SCADA | RPA | BC | BD | IIoT | VR |

| ERP2 | X | X | X | X | X | X | |||

| BI | X | X | |||||||

| MES | X | X | X | ||||||

| SCADA | X | X | |||||||

| RPA | X | ||||||||

| Blockchain | X | ||||||||

| Big data | X | ||||||||

| IIoT | X | X | X | ||||||

| VR | X | X |

Let's build a matrix of subsystems integration included in ERP3 standard. It is easy to see from Tab. 1, that ERP2-system requires the greatest number of modifications to be connected with the components of Industry 4.0 (4 of 5). As a rule, basic package of ERP2-system already contains tools to integrate it with BI and MES-systems that can be customized without any development. Further refinement of integration points, guided by business needs, will allow you to prepare final list of modifications. Thus, transition to ERP3 standard will require significant integration changes in the functionality of ERP2-system.

VI. Evaluation

The ERP3 management standard is relevant for manufacturing enterprises by definition. Firstly, this is emphasized by the presence of MES and SCADA strategies. Secondly, the management concepts of IIoT, VR and RPA are now mainly used in manufactories. And, thirdly, ERP2 standard covers absolutely all areas of the organization's activities, which is typical for enterprises of resource and product orientations. The application of blockchain strategy will ensure continuous control of the transmitted financial and sensitive data. The concept of RPA will allow you to minimize manual routine operations, which often leads to errors. Using VR approach to visualize product samples will enable early detection and correction of design collisions. Industrial IoT will set the foundation for building smart manufacturing. The use of big data and BI standards will ensure stable control of the operational production environment.

Corporate information systems will bring the ERP3 standard to life. ERP3-systems will be represented by a set of integrated software solutions, most likely from various vendors. Therefore, similarly to ERP2-systems, the term ERP3-system will be synthetic in nature. At the moment, there are no software products labeled ERP2-systems and enterprise where ERP2-system is successfully used may simply not know about it. Deployment of ERP3-systems will be based on several implementation methodologies, the most critical components of ERP2, MES and SCADA will require the use of a cascade model, while for the rest it is reasonable to apply iterative and spiral Agile based approaches. The relevance of sustainability topic will impose restrictions on the technical implementation of software solutions, the transition of applications and data to the cloud platform is very likely. The average duration of ERP3-system implementation project will start from two years.

The use of ERP3 standard and its technical implementation in ERP3-systems will allow to build end-to-end business processes of enterprise with maximum coverage of operations and traceability of documents. New technological components of corporate system such as IIoT, VR, RPA and others will be placed in independent subsystems, which will provide flexibility in building an IT architecture and will not require significant modification of ERP2-system at the time of productive go-live. The obvious disadvantages of ERP3-systems include high efforts for the implementation and support. However, over the past few decades, the approach to increase functionality of the information system through gradual integration with independent software solutions has remained unchanged. The situation with ERP3-systems does not seem to be an exception.

Conclusions

There is a new standard to manage corporate information systems focused on the fourth industrial revolution discussed in the paper. The relationship between transition of enterprise to a digital format, corporate systems and industrial revolutions is shown. The components of Industry 4.0, consisting of robots, blockchain, big data, industrial internet of things and virtual reality, were briefly considered. The description of ERP2 standard is given. A comparison of Industry 4.0 components and ERP2-systems allowed us to formulate a new class of systems, presumably named as ERP3. ERP3-system is a product of the fourth industrial revolution, focused on digital transformation and the use of the latest digital technologies. The new class of systems extends the existing ERP2 standard by adding Industry 4.0 components in the form of separate program subsystems. Next step for the research is more detail study of using Industry 4.0 components in ERP2, BI, MES and SCADA-systems and subsequent refinement of integration scheme (Tab. 1). This will define roadmap of implementation RPA, IIoT, VR, blockchain and big data in organizations.

References

- Habadi A. An Introduction to ERP-systems: architecture, implementation and impacts, International journal of computer applications, 2017, vol. 167, issue 9, p. 1-4.

- Schwab I. Shaping the fourth industrial revolution. World Economic Forum, 2018, 289 p.

- Lang V. Digital fluency. APress, 2021, 303 p.

- Lorizio L. Digitalization: the new normal of the post-pandemic world. Independently published, 2021, 105 p.

- Sudakov V. Corporate information systems. MAI, 2016, 96 p. (in Russian).

- Samara T. ERP and information systems. Integration or disintegration. John Wiley & Sons Limited, 2018, 145 p.

- Ali M., Miller L. ERP system implementation in large enterprises – a systematic literature review. Journal of enterprise information management, 2017, vol. 30, issue 1, p. 666-692.

- Stepanov D. Digitalization and corporate information systems. Proceedings of national scientific and practical conference «Degitalization of technosphere: a scientific approach», 2021, p. 108-115. (in press, in Russian).

- Standards of corporate information systems. – URL: https://corpinfosys.ru/knowledgebase/standards (request date: 16.07.2021, in Russian).

- Stepanov D. Analysis, design and development of corporate information systems: theory and practice. Russian technological journal, 2015, vol.8, issue 3, p. 227-238. (in Russian).

Paper details

Dmitry Yu. Stepanov. Shaping ERP3 standard to manage corporate information systems in the time of Industry 4.0 // Proceedings of 3rd International Conference on Control Systems, Mathematical Modeling, Automation and Energy Efficiency. – 2021. – p.100-106. – URL: https://stepanovd.com/science/article/114-2021-5-erp3.